Compressed Air Engineering

Screw Compressor

Hanbell Precise Machinery Co., Ltd. specializes in manufacturing of screw compressors for the industrial markets as well as for air conditioning and refrigeration applications. It is a household name in refrigeration industries for their world renowned refrigeration screw compressors which is exported to most parts of the world. Hanbell started their air compressor division after perfecting the manufacture of screw air ends with their own patented profile.

A deep understanding of its customers has allowed Hanbell Precise Machinery Co., Ltd. with its team of engineers to continue innovating in the design and manufacturing of its products. As a result, Hanbell's products are recognized worldwide for high quality and peak performance.

BY MANUFACTURING ITS OWN ROTORS, HANBELL HAS GAINED THE CONFIDENCE AND TRUST OF CUSTOMERSWORLDWIDE. ALL HANBELL'S AIRENDS ARE TESTED TO MEET HIGHEST QUALITY STANDARDS.

Hanbell's plants are equipped with state of the art automated storage and testing facilities. Hanbell's commitment to its customers is based on "Quality comes first".

CONTEMPORARY DESIGN

Acoustic enclosures reduce sound levels. The compact design of its compressors ensure that minimum space is occupied.

ADVANCED PATENTED PROFILE

Third Generation Alpha Asymmetric 5 to 6 patented rotors profile are designed to operate at the low tip speed with high volumetric efficiency and minimal vibration.

MULTI PROTECTION INTERLOCK

Advanced 32 bit “HANCON” micro controller equipped with pressure transducers and temperature sensors provide diagnostics for additional protection of internal components. Inaddition, by incorporating Modbus communication protocol, one can have multiple master/ and slave controls.

QUALITY CERTIFICATION

Hanbell utilizes 3D measuring devices to strictly maintain high quality standards. Every Hanbell Compressor is well proven and fully tested prior to delivery.

HIGH RIGIDITY CHASIS

Rigid design structure allows for less vibration and low noise during compressor operation. Common base frame is designed for easy handling through forklift.

HEART OF HANBELL COMPRESSORS

When it comes to air end manufacturing, Hanbell has always been market leaders for the quality and precision that goes in its manufac Luring. Hanbell's air end uses T hird Generation Alpha Asymmetric 5 to 6 patented rotors profile which are designed to operate at low tip speed producing high volumetric efficiency and can achieve discharge pressure upto 16 bar. Hanbell air ends are fitted with heavy duty bearings which protects the air end from axial thrusts, thus avoiding damage to rotors and the casing.

DRIVE : OPTIMUM PERFORMANCE

The AA6 series works on direct drive mechanism, the airend takes power coming from the motor without any reductions which is usually in case of belt, pulley, gears, etc. To put it in simple terms, the motor is directly coupled with the rotors which produces the same power as the motor but at low tip speed. This uncomplicated structure reduces the number of components involved, reducing the vibration and resulting in lower noise emission. An additional advantage of the 1:1 drive is that this mechanism has few moving parts, therefore has better durability and minimal maintenance.

INTELLIGENT CONTROL SYSTEM

Hanbell's 6 series compressors are fitted with advanced 32 bytes ”HANCON2W1. micro compuMmontroller, which enables to offer many alarm messages and many errors for protection; it is a versatile controller with smart remote and master/slave alternative control. It constantly monitors the operating param-eters, and stores maintenance and alarm history.

BIGGER SIZED AND EFFECTIVE COOLER

Hanbell compressor uses aluminium vacuum brazed coolers of sufficiently large size and multiple fins helps in effective heat dissipation. A further advantage of having bigger sized cooler is that it can operate with lower sized cooling fans.

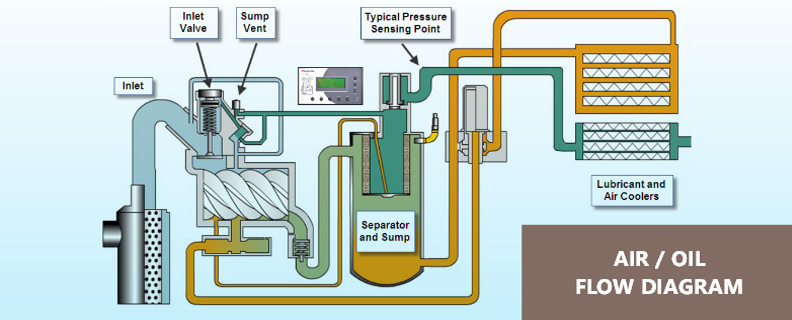

EXCELLENT AFTER COOLER AND OIL COOLING SYSTEM

Uniquely designed cooling system comprising of oil and after cooler lead to higher efficiency in heat exchange thus lowering the working temperature of discharge air and maintaining optimum oil temperature. The advantage of these specially designed fan is, it protects the lubrication system from any condensate formation. Hanbell coolers are sized to work even at high ambient of upto 45°C.

HIGH EFFICIENCY DESIGN

Hanbell's rotors are manufactured using German Leitz CNC 3-D Coordinate measuring machine and QUINDOS Testing software that ensures its incompara-ble precision.

DURABLE RIGID PIPING

All Hanbell compressors are provided with rigid piping. Rigid seamless piping provides additional protecdon against air and oil leakage.

BELT TENSIONSELF - ADJUSTING DESIGN

Belt tension can be adjusted automatically by motor’s own dead weight and balancing. This design can save time spent in shutdown and labour unlike the traditional methods used for replacement of belt.

SPECIFICATION OF AE6

| Model | AE6-08A | AE6-11A | AE6-15A | AE6-18A | AE6-22A | AE6-30A | AE6-37A | AE6-45A | AE6-55A | AE6-75A | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressor | Air Flow | 7 bar | cfm | 42 | 60 | 85 | 113 | 134 | 176 | 226 | 265 | 353 | 494 |

| 0.7 Mpa | m3/min | 1.2 | 1.7 | 2.4 | 3.2 | 3.8 | 5.0 | 6.4 | 7.5 | 10.0 | 14.0 | ||

| 8 bar | cfm | 39 | 56 | 75 | 106 | 127 | 166 | 215 | 251 | 332 | 462 | ||

| 0.8 Mpa | m3/min | 1.1 | 1.6 | 2.2 | 3.0 | 3.6 | 4.7 | 6.1 | 7.1 | 9.4 | 13.1 | ||

| 10 bar | cfm | 35 | 49 | 67 | 95 | 113 | 152 | 191 | 226 | 304 | 416 | ||

| 1.0 Mpa | m3/min | 1.0 | 1.4 | 1.9 | 2.7 | 3.2 | 4.3 | 5.4 | 6.4 | 8.6 | 11.8 | ||

| Air Outlet Size(inch) | 3/4" | 3/4" | 11/4" | 11/4" | 11/4" | 11/4" | 11/4" | 11/4" | 11/4" | 2" | |||

| Trasmission mode | belt driven | ||||||||||||

| Lubricant Volume(L) | 8 | 9 | 10 | 10 | 16 | 18 | 18 | 25 | 60 | 65 | |||

| Motor | Rated Output(kW) | 7.5 | 11 | 15 | 18 | 22 | 30 | 37 | 45 | 55 | 75 | ||

| Rated Output(Hp) | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | |||

| Frequency(Hz) | 50Hz | ||||||||||||

| Type | TEFC | ||||||||||||

| Starting | DOL | Y-Δ | |||||||||||

| Safety Protection | Safety Valve, High Discharge Temperature and Presure Protection, Over Current Protecton, Phase Loss/Phase Sequence Monitoring |

||||||||||||

| Maintanance Indication | Air Filter, Oil Filter, Fine Seperator, Oil Change, Motor Greasing | ||||||||||||

| Micro Controller | Digital Temperature/Pressure Display Control, Auto Running/Stop Control, Timer Running/Stop Control, Master/Slave Interlock Control(Optional), Scalable Central Monitor (Optional). |

||||||||||||

| Net Weight (kg) | 280 | 300 | 380 | 450 | 500 | 700 | 780 | 900 | 1300 | 1500 | |||

| Outline Dimension | Length (mm) | 820 | 870 | 1050 | 1050 | 1150 | 1150 | 1100 | 1100 | 1800 | 1960 | ||

| Width (mm) | 660 | 660 | 700 | 750 | 850 | 850 | 1100 | 1100 | 1300 | 1500 | |||

| Height (mm) | 920 | 980 | 1030 | 1100 | 1300 | 1300 | 1400 | 1400 | 1750 | 1750 | |||

Note: All the above models can also be offered with Variable Frequency Drive (VFD)

SPECIFICATION OF AA6

| Model | AA6-22A | AA6-37A | AA6-45A | AA6-255A | AA6-75A | AA6-90A | AA6-110A | AA6-132A | AA6-160A | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressor | Air Flow | 7 bar | cfm | 138 | 251 | 296 | 371 | 494 | 610 | 752 | 872 | 1052 |

| 0.7 MPa | m3/min | 3.9 | 7.1 | 8.4 | 10.5 | 14.0 | 17.5 | 21.3 | 24.7 | 29.8 | ||

| 8 bar | cfm | 131 | 240 | 282 | 346 | 462 | 593 | 706 | 819 | 995 | ||

| 0.8 Mpa | m3/min | 3.7 | 6.8 | 8.0 | 9.8 | 13.1 | 16.8 | 20.0 | 23.2 | 28.2 | ||

| 10 bar | cfm | 120 | 219 | 247 | 318 | 416 | 494 | 628 | 731 | 889 | ||

| 1.0 Mpa | m3/min | 3.4 | 6.2 | 7.0 | 9.0 | 11.8 | 14.0 | 17.8 | 20.7 | 25.2 | ||

| Air Outlet Size(inch) | 11/4" | 11/4" | 11/4" | 11/4" | 2" | DN65-16 | DN80-16 | DN80-16 | DN80-16 | |||

| Transmission Mode | Direct Coupled Drive | |||||||||||

| Lubricant Volume(L) | 19 | 22.5 | 22.5 | 50 | 50 | 70 | 70 | 70 | 90 | |||

| Motor | Rated Output(kW) | 22 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | 160 | ||

| Rated Output(Hp) | 19 | 22.5 | 22.5 | 50 | 50 | 70 | 70 | 70 | 90 | |||

| Frequency(Hz) | 50Hz | |||||||||||

| Type | TEFC | |||||||||||

| Starting | Y-Δ | |||||||||||

| Safety Protection | Safety Valve, High Discharge Temperature and Presure Protection, Over Current Protecton, Phase Loss/Phase Sequence Monitoring |

|||||||||||

| Maintanance Indication | Air Filter, Oil Filter, Fine Seperator, Oil Change, Motor Greasing | |||||||||||

| Micro Controller | Digital Temperature/Pressure Display Control, Auto Running/Stop Control, Timer Running/Stop Control, Master/Slave Interlock Control(Optional), Scalable Central Monitor (Optional). |

|||||||||||

| Net Weight (kg) | 800 | 900 | 1020 | 1600 | 1900 | 2400 | 2700 | 2700 | 3000 | |||

| Outline Dimension | Length (mm) | 1400 | 1450 | 1500 | 1750 | 1850 | 2150 | 2150 | 2150 | 2950 | ||

| Width (mm) | 802 | 900 | 1150 | 1200 | 1300 | 1460 | 1460 | 1460 | 2100 | |||

| Height (mm) | 1000 | 1400 | 1400 | 1350 | 1400 | 1620 | 1620 | 1620 | 2080 | |||

Note:All the above models can also be offered with Variable Frequency Drive (VFD)