Compressed Air Piping

Hanbell Precise Machinery Co., Ltd. specializes in manufacturing of screw compressors for the industrial markets as well as for air conditioning and refrigeration applications. It is a household name in refrigeration industries for their world renowned refrigeration screw compressors which is exported to most parts of the world. Hanbell started their air compressor division after perfecting the manufacture of screw air ends with their own patented profile.

A deep understanding of its customers has allowed Hanbell Precise Machinery Co., Ltd. with its team of engineers to continue innovating in the design and manufacturing of its products. As a result, Hanbell's products are recognized worldwide for high quality and peak performance.

BY MANUFACTURING ITS OWN ROTORS, HANBELL HAS GAINED THE CONFIDENCE AND TRUST OF CUSTOMERSWORLDWIDE. ALL HANBELL'S AIRENDS ARE TESTED TO MEET HIGHEST QUALITY STANDARDS.

Hanbell's plants are equipped with state of the art automated storage and testing facilities. Hanbell's commitment to its customers is based on "Quality comes first".

CONTEMPORARY DESIGN

Acoustic enclosures reduce sound levels. The compact design of its compressors ensure that minimum space is occupied.

ADVANCED PATENTED PROFILE

Third Generation Alpha Asymmetric 5 to 6 patented rotors profile are designed to operate at the low tip speed with high volumetric efficiency and minimal vibration.

MULTI PROTECTION INTERLOCK

Advanced 32 bit “HANCON” micro controller equipped with pressure transducers and temperature sensors provide diagnostics for additional protection of internal components. Inaddition, by incorporating Modbus communication protocol, one can have multiple master/ and slave controls.

QUALITY CERTIFICATION

Hanbell utilizes 3D measuring devices to strictly maintain high quality standards. Every Hanbell Compressor is well proven and fully tested prior to delivery.

HIGH RIGIDITY CHASIS

Rigid design structure allows for less vibration and low noise during compressor operation. Common base frame is designed for easy handling through forklift.

HEART OF HANBELL COMPRESSORS

When it comes to air end manufacturing, Hanbell has always been market leaders for the quality and precision that goes in its manufac Luring. Hanbell's air end uses T hird Generation Alpha Asymmetric 5 to 6 patented rotors profile which are designed to operate at low tip speed producing high volumetric efficiency and can achieve discharge pressure upto 16 bar. Hanbell air ends are fitted with heavy duty bearings which protects the air end from axial thrusts, thus avoiding damage to rotors and the casing.

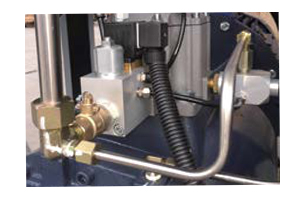

DRIVE : OPTIMUM PERFORMANCE

The AA6 series works on direct drive mechanism, the airend takes power coming from the motor without any reductions which is usually in case of belt, pulley, gears, etc. To put it in simple terms, the motor is directly coupled with the rotors which produces the same power as the motor but at low tip speed. This uncomplicated structure reduces the number of components involved, reducing the vibration and resulting in lower noise emission. An additional advantage of the 1:1 drive is that this mechanism has few moving parts, therefore has better durability and minimal maintenance.

INTELLIGENT CONTROL SYSTEM

Hanbell's 6 series compressors are fitted with advanced 32 bytes ”HANCON2W1. micro compuMmontroller, which enables to offer many alarm messages and many errors for protection; it is a versatile controller with smart remote and master/slave alternative control. It constantly monitors the operating param-eters, and stores maintenance and alarm history.

BIGGER SIZED AND EFFECTIVE COOLER

Hanbell compressor uses aluminium vacuum brazed coolers of sufficiently large size and multiple fins helps in effective heat dissipation. A further advantage of having bigger sized cooler is that it can operate with lower sized cooling fans.

EXCELLENT AFTER COOLER AND OIL COOLING SYSTEM

Uniquely designed cooling system comprising of oil and after cooler lead to higher efficiency in heat exchange thus lowering the working temperature of discharge air and maintaining optimum oil temperature. The advantage of these specially designed fan is, it protects the lubrication system from any condensate formation. Hanbell coolers are sized to work even at high ambient of upto 45°C.

HIGH EFFICIENCY DESIGN

Hanbell's rotors are manufactured using German Leitz CNC 3-D Coordinate measuring machine and QUINDOS Testing software that ensures its incompara-ble precision.

DURABLE RIGID PIPING

All Hanbell compressors are provided with rigid piping. Rigid seamless piping provides additional protecdon against air and oil leakage.

BELT TENSIONSELF - ADJUSTING DESIGN

Belt tension can be adjusted automatically by motor’s own dead weight and balancing. This design can save time spent in shutdown and labour unlike the traditional methods used for replacement of belt.

SPECIFICATION OF AE6

| Model | AE6-08A | AE6-11A | AE6-15A | AE6-18A | AE6-22A | AE6-30A | AE6-37A | AE6-45A | AE6-55A | AE6-75A | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressor | Air Flow | 7 bar | cfm | 42 | 60 | 85 | 113 | 134 | 176 | 226 | 265 | 353 | 494 |

| 0.7 Mpa | m3/min | 1.2 | 1.7 | 2.4 | 3.2 | 3.8 | 5.0 | 6.4 | 7.5 | 10.0 | 14.0 | ||

| 8 bar | cfm | 39 | 56 | 75 | 106 | 127 | 166 | 215 | 251 | 332 | 462 | ||

| 0.8 Mpa | m3/min | 1.1 | 1.6 | 2.2 | 3.0 | 3.6 | 4.7 | 6.1 | 7.1 | 9.4 | 13.1 | ||

| 10 bar | cfm | 35 | 49 | 67 | 95 | 113 | 152 | 191 | 226 | 304 | 416 | ||

| 1.0 Mpa | m3/min | 1.0 | 1.4 | 1.9 | 2.7 | 3.2 | 4.3 | 5.4 | 6.4 | 8.6 | 11.8 | ||

| Air Outlet Size(inch) | 3/4" | 3/4" | 11/4" | 11/4" | 11/4" | 11/4" | 11/4" | 11/4" | 11/4" | 2" | |||

| Trasmission mode | belt driven | ||||||||||||

| Lubricant Volume(L) | 8 | 9 | 10 | 10 | 16 | 18 | 18 | 25 | 60 | 65 | |||

| Motor | Rated Output(kW) | 7.5 | 11 | 15 | 18 | 22 | 30 | 37 | 45 | 55 | 75 | ||

| Rated Output(Hp) | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | |||

| Frequency(Hz) | 50Hz | ||||||||||||

| Type | TEFC | ||||||||||||

| Starting | DOL | Y-Δ | |||||||||||

| Safety Protection | Safety Valve, High Discharge Temperature and Presure Protection, Over Current Protecton, Phase Loss/Phase Sequence Monitoring |

||||||||||||

| Maintanance Indication | Air Filter, Oil Filter, Fine Seperator, Oil Change, Motor Greasing | ||||||||||||

| Micro Controller | Digital Temperature/Pressure Display Control, Auto Running/Stop Control, Timer Running/Stop Control, Master/Slave Interlock Control(Optional), Scalable Central Monitor (Optional). |

||||||||||||

| Net Weight (kg) | 280 | 300 | 380 | 450 | 500 | 700 | 780 | 900 | 1300 | 1500 | |||

| Outline Dimension | Length (mm) | 820 | 870 | 1050 | 1050 | 1150 | 1150 | 1100 | 1100 | 1800 | 1960 | ||

| Width (mm) | 660 | 660 | 700 | 750 | 850 | 850 | 1100 | 1100 | 1300 | 1500 | |||

| Height (mm) | 920 | 980 | 1030 | 1100 | 1300 | 1300 | 1400 | 1400 | 1750 | 1750 | |||

Note: All the above models can also be offered with Variable Frequency Drive (VFD)

SPECIFICATION OF AA6

| Model | AA6-22A | AA6-37A | AA6-45A | AA6-255A | AA6-75A | AA6-90A | AA6-110A | AA6-132A | AA6-160A | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressor | Air Flow | 7 bar | cfm | 138 | 251 | 296 | 371 | 494 | 610 | 752 | 872 | 1052 |

| 0.7 MPa | m3/min | 3.9 | 7.1 | 8.4 | 10.5 | 14.0 | 17.5 | 21.3 | 24.7 | 29.8 | ||

| 8 bar | cfm | 131 | 240 | 282 | 346 | 462 | 593 | 706 | 819 | 995 | ||

| 0.8 Mpa | m3/min | 3.7 | 6.8 | 8.0 | 9.8 | 13.1 | 16.8 | 20.0 | 23.2 | 28.2 | ||

| 10 bar | cfm | 120 | 219 | 247 | 318 | 416 | 494 | 628 | 731 | 889 | ||

| 1.0 Mpa | m3/min | 3.4 | 6.2 | 7.0 | 9.0 | 11.8 | 14.0 | 17.8 | 20.7 | 25.2 | ||

| Air Outlet Size(inch) | 11/4" | 11/4" | 11/4" | 11/4" | 2" | DN65-16 | DN80-16 | DN80-16 | DN80-16 | |||

| Transmission Mode | Direct Coupled Drive | |||||||||||

| Lubricant Volume(L) | 19 | 22.5 | 22.5 | 50 | 50 | 70 | 70 | 70 | 90 | |||

| Motor | Rated Output(kW) | 22 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | 160 | ||

| Rated Output(Hp) | 19 | 22.5 | 22.5 | 50 | 50 | 70 | 70 | 70 | 90 | |||

| Frequency(Hz) | 50Hz | |||||||||||

| Type | TEFC | |||||||||||

| Starting | Y-Δ | |||||||||||

| Safety Protection | Safety Valve, High Discharge Temperature and Presure Protection, Over Current Protecton, Phase Loss/Phase Sequence Monitoring |

|||||||||||

| Maintanance Indication | Air Filter, Oil Filter, Fine Seperator, Oil Change, Motor Greasing | |||||||||||

| Micro Controller | Digital Temperature/Pressure Display Control, Auto Running/Stop Control, Timer Running/Stop Control, Master/Slave Interlock Control(Optional), Scalable Central Monitor (Optional). |

|||||||||||

| Net Weight (kg) | 800 | 900 | 1020 | 1600 | 1900 | 2400 | 2700 | 2700 | 3000 | |||

| Outline Dimension | Length (mm) | 1400 | 1450 | 1500 | 1750 | 1850 | 2150 | 2150 | 2150 | 2950 | ||

| Width (mm) | 802 | 900 | 1150 | 1200 | 1300 | 1460 | 1460 | 1460 | 2100 | |||

| Height (mm) | 1000 | 1400 | 1400 | 1350 | 1400 | 1620 | 1620 | 1620 | 2080 | |||

Note:All the above models can also be offered with Variable Frequency Drive (VFD)

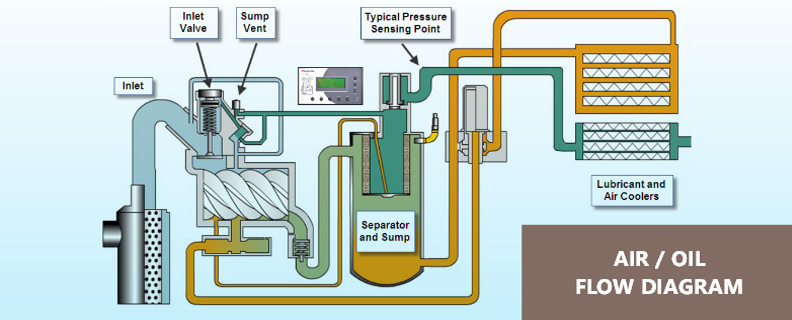

Air Reservoir are manufactured in quality carbon steel for storing compressed air with capacities ranging from 200 litres to 30000 litres.

STANDARDS

Precise design and Manufacture Air Reservoir in accordance with EEC/97/23 for pressure equipment or ASME Pressure Vessel code.

| I | Inlet | d | Drain | p | Pressure switch ∅1/2" |

|---|---|---|---|---|---|

| o | Outlet | m | pressure gauge | v | Safety Valure ∅1" |

| Liters | Dimensions mm | ∅ Connections | ||||

|---|---|---|---|---|---|---|

| A | B | D | H | i-o | Drain(d) | |

| 500 | 543 | 965 | 660 | 1900 | 1 1/2" | 1/2" |

| 1000 | 632 | 1135 | 850 | 2270 | 2"-F | 1/2" |

| 1500 | 700 | 1125 | 1065 | 2400 | 2"-F | 1" |

| 2000 | 690 | 1140 | 1200 | 2400 | 3"-F | 1" |

| 3000 | 725 | 1400 | 1300 | 2800 | 4"-F | 1 1/4" |

| 4000 | 900 | 1500 | 1450 | 3110 | 6"-F | 1 1/2" |

| 5000 | 885 | 1500 | 1600 | 3100 | 6"-F | 1 1/2" |

| 8000 | 885 | 3000 | 1600 | 4600 | 6"-F | 2" |

| 10000 | 885 | 4000 | 1600 | 5600 | 8"-F | 2" |

CONNECTION

Inlet & Outlet Connections can be of screwed end / flanged end

BOTTOM SUPPORTS

Supports can be of Leg or Stud type

PAINTING / POWDER COATING

Air Reservoir upto 3000 Ltrs. are powder coated and other capacity will be painted with RAL 5015. Blue color as standard

WORKING PRESSURE

Air Reservoir are manufactured to 14 bar working pressure as standard (for other pressure please consult factory)

ACCESSORIES

PRESSURE GAUGE

S.S. pressure gauge (Glycerine Filled) is fitted in all air Reservoir as standard

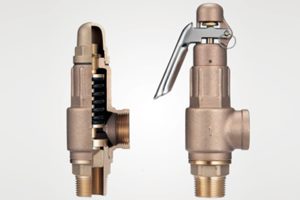

SAFETY VALVE

All Air Reservoir should be fitted with a safety valve to protect the cylinder against over pressure due to malfunction of controls or incorrect operation.

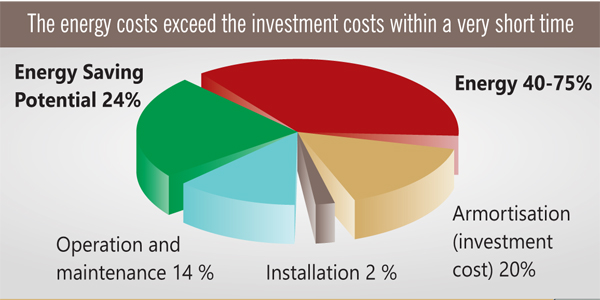

WHY IS COMPRESSED AIR PROCESSED?

Compressed air is an essential form of driving and process energy in all fields of industrial and production manufacturing. Compressed air must be dry, free of oil and clean to avoid expensive production breakdowns.

Compressed air is produced by compressing air which is sucked into the compressor. This usually contains pollutants, dirt particles and always moisture in the form of water vapour, which condenses spontaneously in the compressed air and can then lead to disruptions in operations and thereby to substantial but avoidable costs.

HOW DOES A DRYER WORK?

To process the compressed air, it is fed into the refrigeration compressed air dryer and is pre-cooled in an air/air heat exchanger. This pre-cooling is conducted in counter-flow with the expelled, cooled compressed air and therefore operates completely without additional energy.

Further cooling to the pressure dewpoint is conducted in a refrigerant/air heat exchanger cooled by a refrigerant cycle. Throughout the entire cooling process, moisture is precipitated from the compressed air as condensate and is automatically drained. Before being expelled the processed compressed air is re-heated in the air/air heat exchanger by means of the entering compressed air.

FEATURES AND ADVANTAGES

PLC DISPLAY

AIR DRYER TECHNICAL SPECIFICATIONS

| MODEL NO | FLOW RATE (cfm) |

OP. PR. (Kg/cm2) |

POWER (Voltage) |

CURRENT (Phase) |

INST. POWER HP |

CONNECTIONS BSP/Flange |

DIMENSIONS | REFRIGERANT USED |

||

|---|---|---|---|---|---|---|---|---|---|---|

| ARTD 003 | 30 | 16 | 230 | 1 | 0.5 | 1/2" | 300 | 400 | 600 | R134a |

| ATRD 004 | 40 | 16 | 230 | 1 | 0.5 | 1/2" | 400 | 450 | 760 | R134a |

| ARTD 007 | 70 | 16 | 230 | 1 | 1 | 1" | 400 | 450 | 760 | R134a |

| ARTD 008 | 80 | 16 | 230 | 1 | 1 | 1" | 450 | 550 | 975 | R134a |

| ATRD 012 | 120 | 16 | 230 | 1 | 1 | 1 1/2" | 450 | 550 | 975 | R134a/22 |

| ARTD 015 | 150 | 16 | 230 | 1 | 1 | 1 1/2" | 530 | 650 | 1080 | R134a/22 |

| ARTD 018 | 180 | 16 | 230 | 1 | 1 | 1 1/2" | 530 | 650 | 1080 | R134a/22 |

| ARTD 020 | 200 | 12 | 230 | 1 | 1 | 1 1/2" | 530 | 650 | 1080 | R134a/22 |

| ARTD 025 | 250 | 12 | 230 | 1 | 1 | 1 1/2" | 530 | 650 | 1080 | R22a/404 |

| ATRD 035 | 300 | 12 | 230 | 1 | 1 | 2" | 750 | 1000 | 1500 | R22a/405 |

| ARTD 040 | 400 | 12 | 230 | 1 | 1.5 | 2" | 750 | 1000 | 1500 | R22a/406 |

| ARTD 050 | 500 | 12 | 440 | 3 | 1.5 | 2" | 1400 | 1200 | 1500 | R22a/407 |

| ARTD 061 | 620 | 12 | 440 | 3 | 1.5 | 3" Flg | 1400 | 1200 | 1500 | R22a/408 |

| ARTD 065 | 650 | 12 | 440 | 3 | 1.5 | 3" Flg | 1400 | 1200 | 1500 | R22a/409 |

| ARTD 075 | 750 | 12 | 440 | 3 | 1.5 | 3" Flg | 1400 | 1200 | 1500 | R22a/410 |

| ARTD 090 | 900 | 12 | 440 | 3 | 1.5 | 3" Flg | 1400 | 1200 | 1780 | R22a/411 |

| ARTD 100 | 1000 | 12 | 440 | 3 | 2 | 4" Flg | 1700 | 1900 | 1800 | R22a/412 |

| ARTD 130 | 1300 | 12 | 440 | 3 | 2 | 4" Flg | 1700 | 1900 | 1800 | R22a/413 |

| ARTD 170 | 1700 | 12 | 440 | 3 | 2 | 4" Flg | 2450 | 2800 | 1800 | R22a/414 |

| ARTD 200 | 2000 | 12 | 440 | 3 | 2 | 4" Flg | 2450 | 2800 | 1800 | R22a/415 |

| ARTD 230 | 2300 | 12 | 440 | 3 | 2 | 4" Flg | 2600 | 2800 | 1950 | R22a/416 |

| ARTD 270 | 2700 | 12 | 440 | 3 | 2 | 4" Flg | 2600 | 2800 | 1950 | R22a/417 |

The Flow rates indicated is based on compressor room temperature of 30 - 30 deg C, operating pressure of 7 Kg/cm2g and ambient 35 deg, maintaining the dew point of 2 - 10 deg C. * Due to our development of the product, we reserve the right to modify the specification without prior notice.

HIGH EFFICIENCY COMPRESSED AIR FILTRATION

The reliability of compressed air filtration is paramount to the on going fight against problems caused through contamination entering the air system. Contamination in the form of dirt, oil and water can lead to:

The AIRTECH filtration range offers various products and grades of filtration to provide peace of mind whatever the air quality requirement.Compressed air contamination will ultimately lead to :

LOW AIR LOSE DRAIN VALVE

Auto drain valve electrical timer

Speciality

MECHANICAL FLOAT TYPE DRAIN VALVE

| ITEM NAME | CS72BA | PS DRAIN VALVE |

|---|---|---|

| Type | Normal Close | * |

| Working Medium | Water | Water |

| Oriface | 3.5 mm | 4m |

| Portsize | NPT.BSP 1/2" | * |

| Working Pressure | 0-16 bar | 0-16 bar |

| Working Temperature | 0-80 c, 0-120 c | 90c |

| Voltage | AC/DC24V - 240V | AC/DC24V - 240V |

| Impulsion Rate | Class H, IP65 | Class H, IP65 |

| Body Material | Brass | Brass |

| Seal | NBR, VITON | NBR, VITON |

UNIQUE SPECIAL APPLICATION TOOLS & SYSTEMS

Ergonomic eX Blow gun

Cable & Tube Wiper, Real Wipe CWR-16

Vac in Line

Water Spray Nozzles SPS-13

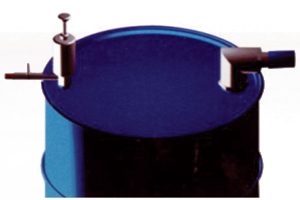

Barrel filling and emptying system RAPFLO-17

Appliances division

RANGE OF COMPRESSED AIR SAVING PRODUCTS

Ergonomical Blowgun PSH-7

Real blow nozzle RBA-2 & RBS-3

Real blow High thrust jet HTB-4

Real blow pipe RBP-5

Vac Blow gun VBG-14

Real Vac RVC-15